Sterile Drug Products

Manufacturing

through our proven technical expertise and

comprehensive sterility assurance system.

Service Overview

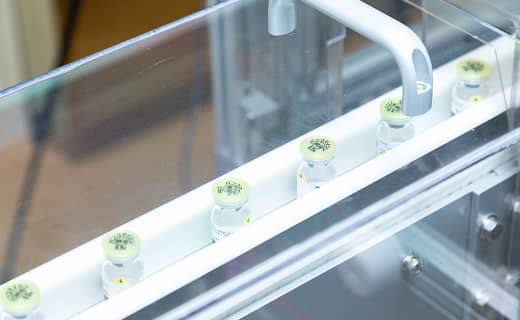

We provide contract manufacturing of Sterile Drug Products under a comprehensive sterility assurance system.

In manufacturing, we use MES (Manufacturing Execution System) to manage the weighing and charging processes, which helps to prevent

cross-contamination.

We are proud of our decades-long commitment to solve social issues, driven by our mission to provide a steady supply of essential medicines. We are constantly pursuing a higher level of quality assurance, not just meeting the minimum requirements of regulatory

inspections.

Characteristics

provide solutions tailored to our customers' needs.

-

Appropriate aseptic environment

- The sterile manufacturing area is designed to minimize the risk of contamination during the manufacturing process and provides an appropriate aseptic environment.

-

Manufacturing in compliance with cGMP

- With deep expertise in raw material quality assurance and a thorough understanding of aseptic techniques, our specialized staff performs production in compliance with cGMP.

-

Thorough implementation of the monitoring improvement cycle

- To further enhance our sterility assurance, we regularly monitor the sterile environment and

periodically evaluate the operation status of the production lines to ensure continuous improvements. -

Experience in building single-use production lines

- With our deep understanding of customers' needs, we have experience in building customized single-use aseptic production lines to ensure the supply of products with guaranteed sterility.

CDMO Available Manufacturing and Development Support

We offer a range of dosage form contract manufacturing

We can handle filling of vials, syringes, and powders formulations

(Lyophilized products)

- Filling line (1) : 100 vials/ min,

freeze dryer (1) - Packaging line (1) : 250 vials/min

- Inspection line (1)

- Glass syringe filling line (1) :

80 syringes/min - Plastic syringe filling line (1) :

120 syringes/min - Packaging line (1) : 140 syringes/min

- Mixer (1)

- Filling line (1) : 70 vials/min (Isolator)

- Packaging line (2)

Development Support

Comprehensive technical consulting services

To optimize the stability of injectable drugs, the freeze-drying cycle time is a top priority on those development. To explore high-quality injectable drug manufacturing, we have a technical development area on-site where we support everything from initial

condition studies and prototype manufacturing to clinical trial drug production. To ensure a reliable simulation of commercial production, we have a non-GMP pilot-scale manufacturing facility in this area. This setup allows us to seamlessly progress from initial formulation studies to

full-scale prototype manufacturing.

We also offer flexible support for product-specific filter validation and process simulation.

Other Products

Inquiries about Our Business Activities

CMO business email address.